Off-Highway Engine Cooling has been our passion for three generations

Josephson Manufacturing Company (JMC) is a third generation family owned heat-transfer company. We design, engineer, and manufacture the highest quality engine cooling systems and components available in today’s marketplace. Our successful history has been built on partnering with our customers to develop a perspective of what it takes to exceed their customer’s expectations while maintaining a competitive edge in the marketplace.

We recognize that to help our customers succeed, they need to get their products to market as quickly as possible. You can rely on JMC to respond with urgency and to get the job done right the first time. JMC is looking forward to the cooling challenges that lie ahead by developing new product and service capabilities that will deliver the same high standard of performance and durability under harsher and more complex operating conditions.

A History of Thermal Management

The Early Years

Herb Josephson served his country with the United States Air Force during World War II. Upon returning from Europe, Herb started the radiator repair shop in 1949. He repaired and serviced all types of heat exchangers. Herb was also the regional distributor for Modine Truck & Bus radiators and cores.

Off-Highway & Beyond

Herb’s son John Josephson took over in 1972. In 1988, Josephson Manufacturing Company began manufacturing and selling to off highway OEMs. John’s sons Erik and Andy continue operating the company today, developing new product lines such as mechanical bond radiators for locomotives and stainless steel heat exchangers for oil and gas industries.

A Continued Dedication to Excellence

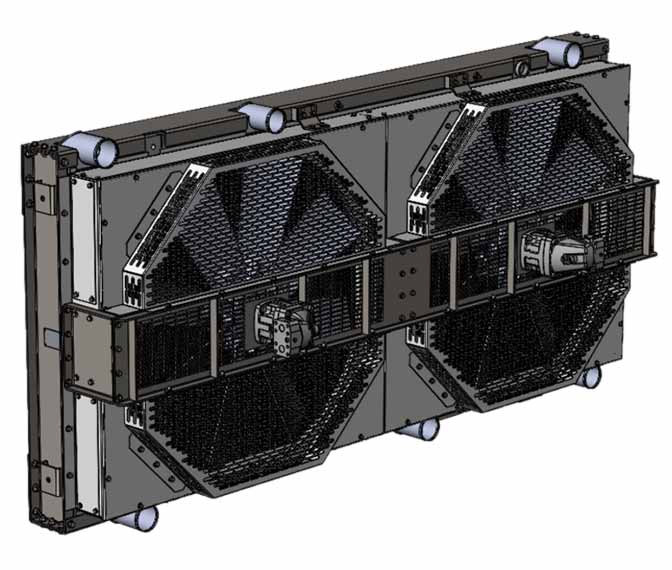

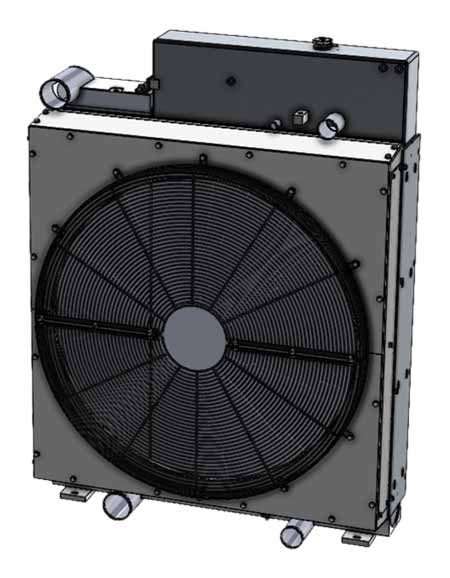

Josephson Manufacturing Company designs complete cooling assemblies, providing solutions for the most demanding applications. Josephson offers a complete line of engine cooling systems and components along with custom engineering service and support. Responsive service combined with total quality philosophy – you build value when you build with Josephson.

With over 40 years experience servicing OEM’s, you can count on Josephson for your cooling needs.

Building Solutions Together

A Family Business

JMC employs the most modern equipment and manufacturing systems in a New 90,000 sq ft facility located in Fort Dodge, Iowa.

Retrofitting aftermarket OEM replacement products for new and obsolete equipment.

Products That Stand the Test of Time

JMC has over 15 years of continuous registration in ISO9001:2015 standards.

Cross-trained teams of employees and technicians ensure quality while expanding manufacturing capacity.

Made in the USA

JMC proudly supports American industry – Oil & Gas, Agriculture, Construction, Mining, Defense, and Power Generation.

JMC also thanks our partners from around the world.

We Salute You!

JMC’s High Efficiency Heat Transfer Products Expand Your Machinery’s Capacity, Lifespan and Capabilities.

JMC manufactures a variety of off-highway engine cooling systems and heat transfer products, components, accessories, and kits. From custom builds to OEM replacements, we have the solution for you. Check out our product categories. If you don't see what you need, just contact us and see what JMC can do for you.