Protect Your Valued Equipment & Hardware from overheating

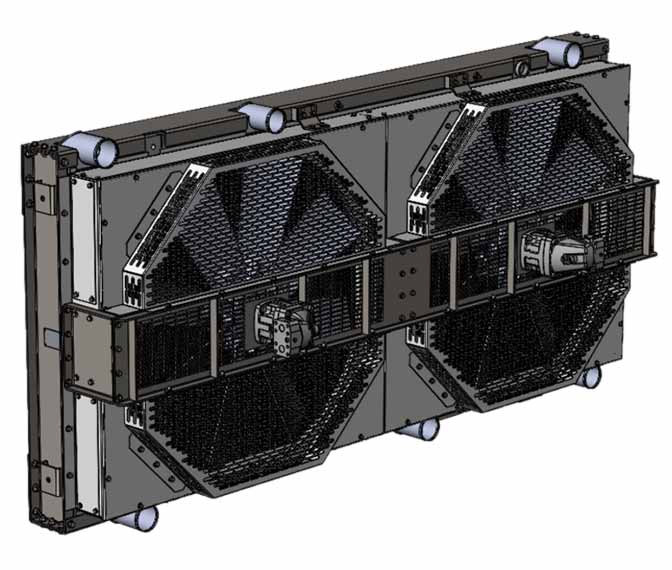

Josephson Manufacturing Company (JMC) of Fort Dodge, Iowa is a custom designer and manufacturer of heat transfer products. JMC designs and builds radiators, charge air coolers, oil coolers, and cooling components as well as complete engine cooling systems.

Technology

Our on-site laboratory boasts the latest analysis tools for research and development. JMC can simulate the demanding conditions our clients require thier heat transfer solutions to perform under.

Quality

We pride ourselves in producing the consistent quality you expect. Our efficient manufacturing environment reduces waste and ensures satisfaction.

Service

JMC’s sales support team offers customer service and tech support. You deserve accurate and timely communication about JMC products. Responding with urgency and meeting customer needs is what sets us apart.

Innovation

Innovation is key for meeting client needs. JMC is planning for the future of heat transfer products by developing technologies and methods to accommodate Tier 4 requirements and beyond.

Flexible Manufacturing

JMC’s product designers can rapidly develop complete designs using proprietary software and modern design tools, enabling our customers to get their new products to market faster.

Precision

Heavy duty, cost effective, and precision components for the most demanding OEM applications. JMC uses aluminum and copper materials to provide excellent engine cooling solutions.

The JMC Promise

At JOSEPHSON MANUFACTURING COMPANY (JMC), we recognize that in order to help our customers succeed, our heat transfer products need to be brought to market as quickly as possible. You can rely on JMC to respond with urgency and get the job done right the first time.

Our promise to our customers is to design, engineer, and manufacture the highest quality cooling systems and components available in today’s marketplace.

JMC is Engineering Heat Transfer Products for the Machines of the Future

At the heart of the JMC engineering department is one fundamental idea, precision guided by expertise.

Pride in our product and our engineering department fuels our drive for constant process improvement. JMC employees are dedicated to their craft, maintaining a strong sense of ownership in their processes and products.

Combining scientific fundamentals and hands-on practical manufacturing

JMC’s expert engineers and technicians are dedicated to our customers.

Creating heat transfer products and engine cooling solutions that protect our customers’ valuable equipment is priority number one at JMC.

CAD modeling (3-D modeling) is the standard starting point in our manufacturing process. We utilize Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to validate and maximize our design and engineering efforts. More about JMC…

Dedication to excellence should not stop once the project is complete

Upon completion of a heat transfer product, JMC continues running it through a series of performance and endurance tests. The results are analyzed – discoveries and improvements are integrated into the product, ultimately benefitting you, the end user.

This process of design, engineering, and testing is a part of JMC’s ongoing effort to improve the quality and value of our products and extend the life of our customers’ machinery. Check out our product lineup…

Contact JMC Today!

Want to learn more? Please feel free to contact us us today and speak with our knowledgeable customer service representatives who are happy to help fulfill your equipment needs.

JMC’s High Efficiency Heat Transfer Products Expand Your Machinery’s Capacity, Lifespan and Capabilities.

JMC manufactures a variety of off-highway engine cooling systems and heat transfer products, components, accessories, and kits. From custom builds to OEM replacements, we have the solution for you. Check out our product categories. If you don't see what you need, just contact us and see what JMC can do for you.